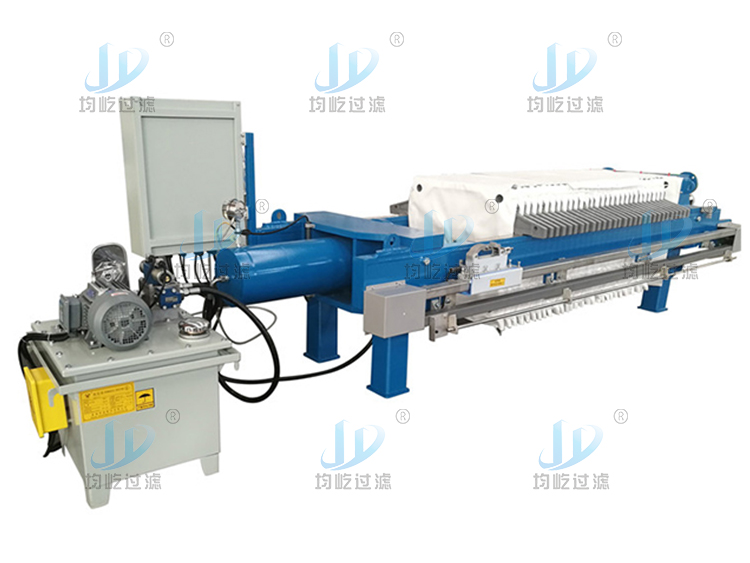

Igumbi elizenzekelayo lentsimbi yentsimbi ye-carbon steel filter press kunye nepompo ye-diaphragm

Isishwankathelo seMveliso:

Ukucoca igumbi lokucoca sisixhobo sokwahlula esiqinileyo esilulwelo esisebenza ngokwemigaqo ye-high-pressure extrusion kunye nokucoca ilaphu lokucoca. Ifanelekile kunyango lwe-dehydration ye-high-viscosity kunye ne-fine particle materials kwaye isetyenziswa ngokubanzi kumashishini afana nobunjineli beekhemikhali, i-metallurgy, ukutya kunye nokukhuselwa kwendalo.

Iimpawu eziphambili:

Ukutshatyalaliswa koxinzelelo oluphezulu - Ukusebenzisa i-hydraulic okanye i-mechanical pressing system ukubonelela ngamandla anamandla okucoca, ukunciphisa kakhulu umswakama wekhekhe lokucoca.

Ukulungelelaniswa kwe-Flexible - Inani leepleyiti zokucoca kunye nommandla wokucoca unokulungiswa ukuhlangabezana neemfuno ezahlukeneyo zamandla okuvelisa, kunye nokulungiswa kwezinto ezikhethekileyo kuxhaswa (ezifana ne-corrosion-resistant / high-temperature design).

Izinzile kwaye zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala khona.

Iindawo ezisebenzayo:

Ukwahlulwa kolwelo oluqinileyo kunye nokomiswa kwimimandla efana neekhemikhali ezintle, ukucokiswa kweeminerali, udaka lweceramic, kunye nokucocwa kwelindle.

Iimpawu zeMveliso

A,Uxinzelelo lokuhluza<0.5Mpa

B,Ubushushu bokucoca:45℃ / ubushushu begumbi; 80℃/ ubushushu obuphezulu; 100℃/ Ubushushu obuphezulu. Umlinganiselo wempahla ekrwada yeepleyiti zokucoca ubushushu ezahlukeneyo azifani, kwaye ubukhulu beepleyiti zokucoca azifani.

C-1,Indlela yokukhupha - ukuhamba okuvulekileyo: Iifaucets kufuneka zifakwe ngaphantsi kwecala lasekhohlo nasekunene kwipleyiti yokucoca nganye, kunye nesinki ehambelanayo. Ukuqukuqela okuvulekileyo kusetyenziselwa ulwelo olungabuyiswanga.

C-2,Indlela yokukhupha ulwelo clahlekelwaflow:Ngaphantsi kwesiphelo somxhesho wokucoca, kukho ezimbinikufutshaneimibhobho engundoqo yokuphuma, edityaniswe netanki yokubuyisela ulwelo.Ukuba ulwelo lufuna ukufunyanwa kwakhona, okanye ukuba ulwelo luyaguquguquka, luyanuka, lunokutsha kwaye luyaqhuma, kusetyenziswa ukuqukuqela okumnyama.

D-1,Ukukhethwa kwempahla yelaphu lokucoca: I-pH yolwelo imisela izinto zelaphu lokucoca. I-PH1-5 lilaphu lokucoca i-polyester eneasidi, i-PH8-14 lilaphu lokucoca i-alkaline polypropylene. Ulwelo lwe-viscous okanye okuqinileyo kuyakhethwa ukukhetha ilaphu le-twill lokucoca, kunye nolwelo olungabonisi mehlo okanye okuqinileyo kuyakhethwa ilaphu lokucoca elicacileyo..

D-2,Ukukhethwa kwemesh yelaphu lokucoca: Ulwelo luhlulwe, kwaye inombolo ye-mesh ehambelanayo ikhethwa kwiisayizi ezahlukeneyo zamasuntswana aqinileyo. Umnatha welaphu lokuhluza uluhlu lwe-100-1000 ye-mesh. Ukuguqulwa kweMicron kwimesh (1UM = 15,000 mesh-kwiithiyori).

E,Unyango lomphezulu weRakhi:Ixabiso le-PH elingathathi hlangothi okanye isiseko se-asidi esibuthathaka; Umphezulu wesakhelo sokucinezela isihluzi siqhunyiswa yisanti kuqala, kwaye emva koko sitshizwe nge-primer kunye nepeyinti echasayo. Ixabiso le-PH yi-asidi eyomeleleyo okanye i-alkaline eyomeleleyo, umphezulu wesakhelo sokucofa isihluzi sigalelwe isanti, sitshizwe ngeprimer, kwaye umphezulu usongelwe ngentsimbi engatyiwayo okanye ipleyiti yePP.

FIsihluzi sokuvasa ikeyiki: Xa izinto eziqinileyo zifuna ukufunyanwa, ikeyiki yokucoca i-acidic kakhulu okanye i-alkaline; Xa ikhekhe lokucoca kufuneka lihlanjwe ngamanzi, nceda uthumele i-imeyile ukuze ubuze malunga nendlela yokuhlamba.

G,Ukukhetha impompo yokucoca isihluzi:Umlinganiselo oqinileyo wolwelo, iasidi, ubushushu kunye neempawu zolwelo zahlukile, ngoko ke kufuneka iimpompo zesondlo ezahlukeneyo. Nceda uthumele i-imeyile ukuze ubuze.