I-diaphragm filter cofa ngesixhobo sokucoca ilaphu

✧ Iimpawu zeMveliso

Isixhobo sokucoca isihluzi se-diaphragm: Isihambisi sebhanti, i-flap yokwamkela ulwelo, ilaphu lokuhluza inkqubo yokuhlamba amanzi, ihopha yokugcina udaka, njl.

A-1. Uxinzelelo lokuhluza: 0.8Mpa; 1.0Mpa; 1.3Mpa; 1.6Mpa. (Ngokhetho)

A-2. I-diaphragm ecudisa uxinzelelo lwekeyiki: 1.0Mpa; 1.3Mpa; 1.6Mpa. (Ngokhetho)

B, Ubushushu bokucoca: 45 ℃ / ubushushu begumbi; 65-85℃/ ubushushu obuphezulu.(Ngokuzikhethela)

C-1. Indlela yokukhupha - ukuhamba okuvulekileyo: Iifaucets kufuneka zifakwe ngaphantsi kwecala lasekhohlo nasekunene kwipleyiti yokucoca nganye, kunye nesinki ehambelanayo. Ukuqukuqela okuvulekileyo kusetyenziselwa ulwelo olungabuyiswanga.

C-2. Indlela yokukhutshwa kolwelo -ukuhamba okuvalayo:Ngaphantsi kwesiphelo somxhesho wokucoca, kukho imibhobho emibini esondeleyo yokuphuma, edityaniswe netanki yokubuyisela ulwelo. Ukuba ulwelo lufuna ukufunyanwa kwakhona, okanye ukuba ulwelo luyaguquguquka, luyanuka, lunokutsha kwaye luyaqhuma, kusetyenziswa ukuqukuqela okumnyama.

D-1. Ukukhethwa kwempahla yelaphu lokucoca: I-PH yolwelo imisela imathiriyeli yelaphu lokucoca. I-PH1-5 lilaphu lokucoca i-polyester eneasidi, i-PH8-14 lilaphu lokucoca i-alkaline polypropylene. Ulwelo lwe-viscous okanye okuqinileyo kuyakhethwa ukuba ukhethe ilaphu lokucoca i-twill, kunye nolwelo olungenayo i-viscous okanye oluqinileyo lukhethwa ilaphu lokucoca elicacileyo.

D-2. Ukukhethwa kwemesh yelaphu lokucoca: Ulwelo lwahluliwe, kwaye inombolo yemesh ehambelanayo ikhethwa kwiisayizi ezahlukeneyo zamasuntswana aqinileyo. Umnatha welaphu lokuhluza uluhlu lwe-100-1000 ye-mesh. Ukuguqulwa kweMicron kwimesh (1UM = 15,000 mesh---kwithiyori).

Unyango lwe-E.Rack surface: ixabiso le-PH elingathathi hlangothi okanye isiseko se-asidi esibuthathaka; Umphezulu wesakhelo sokucinezela isihluzi siqhunyiswa yisanti kuqala, kwaye emva koko sitshizwe nge-primer kunye nepeyinti echasayo. Ixabiso le-PH yi-asidi eyomeleleyo okanye i-alkaline eyomeleleyo, umphezulu wesakhelo sokucofa isihluzi sigalelwe isanti, sitshizwe ngeprimer, kwaye umphezulu usongelwe ngentsimbi engatyiwayo okanye ipleyiti yePP.

Umsebenzi wokucoca i-F.Diaphragm filter: I-Automatic Hydraulic Pressing; Ukuhlamba ikeyiki yesihluzi, Ukutsalwa kwepleyiti yesihluzi esizenzekelayo; Ukukhutshwa kweCake yesihluzi sokungcangcazela; Isihluzo esiziSebenzisayo seLaphu lokuHlangula inkqubo. Nceda undixelele imisebenzi oyifunayo ngaphambi koku-odola.

Ukuhlamba ikeyiki yeG.Filter: Xa izinto eziqinileyo zifuna ukufunyanwa kwakhona, ikeyiki yokucoca i-acidic kakhulu okanye ialkaline; Xa ikhekhe lokucoca kufuneka lihlanjwe ngamanzi, nceda uthumele i-imeyile ukuze ubuze malunga nendlela yokuhlamba.

I-H.I-Filter yokukhetha ipompo yokutya yokucoca: Umlinganiselo we-slid-liquid, i-acidity, iqondo lokushisa kunye neempawu zolwelo ziyahluka, ngoko ke iimpompo zokutya ezahlukeneyo ziyafuneka. Nceda uthumele i-imeyile ukuze ubuze.

I.I-Automatic belt conveyor: I-belt conveyor ifakwe phantsi kwe-plate ye-filter press, esetyenziselwa ukuthutha ikhekhe ekhutshwe emva kokuba iiplati zokucoca zikhutshwe zivuliwe. Esi sixhobo sifanelekile kwiprojekthi engafanelekanga ukwenza umgangatho wesiseko. Inokuhambisa ikhekhe kwindawo echongiweyo, eya kunciphisa umsebenzi omningi wabasebenzi.

I-J.I-automatic dripping tray: I-drip tray ifakwe phantsi kwepleyiti yokucoca. Ngethuba lenkqubo yokucoca, iitrayi zeplate ezimbini zikwisimo esivaliweyo, esinokukhokelela ulwelo oluthontsizayo ngexesha lokuhluza kunye namanzi okuhlamba amalaphu kumqokeleli wamanzi emacaleni. Emva kokucoca, iitreyi zeeplate ezimbini ziya kuvulwa ukuze zikhuphe ikhekhe.

K.Isihluzo sokucoca ilaphu lokugungxulwa kwamanzi inkqubo: Ifakwe ngentla komqadi ophambili wokucoca, kwaye ixhotyiswe ngomsebenzi wokuhamba ngokuzenzekelayo, kwaye ilaphu lokucoca lihlanjululwa ngokuzenzekelayo ngamanzi oxinzelelo oluphezulu (36.0Mpa) ngokutshintsha ivalve. Kukho iintlobo ezimbini zezakhiwo zokuhlanjululwa: ukuhlanjululwa kwecala elinye kunye necala eliphindwe kabini, apho ukuhlanjululwa kwecala eliphindwe kabini kuneebhrashi zokucoca kakuhle. Ngomatshini we-flap, amanzi okuhlanjululwa angaphinda asetyenziswe kwaye asetyenziswe kwakhona emva konyango ukuze kugcinwe izibonelelo; idityaniswe nenkqubo yokucinezela i-diaphragm, inokufumana umxholo wamanzi aphantsi; isakhelo esidibeneyo, isakhiwo esincinci, kulula ukuchithwa kunye nokuthutha.

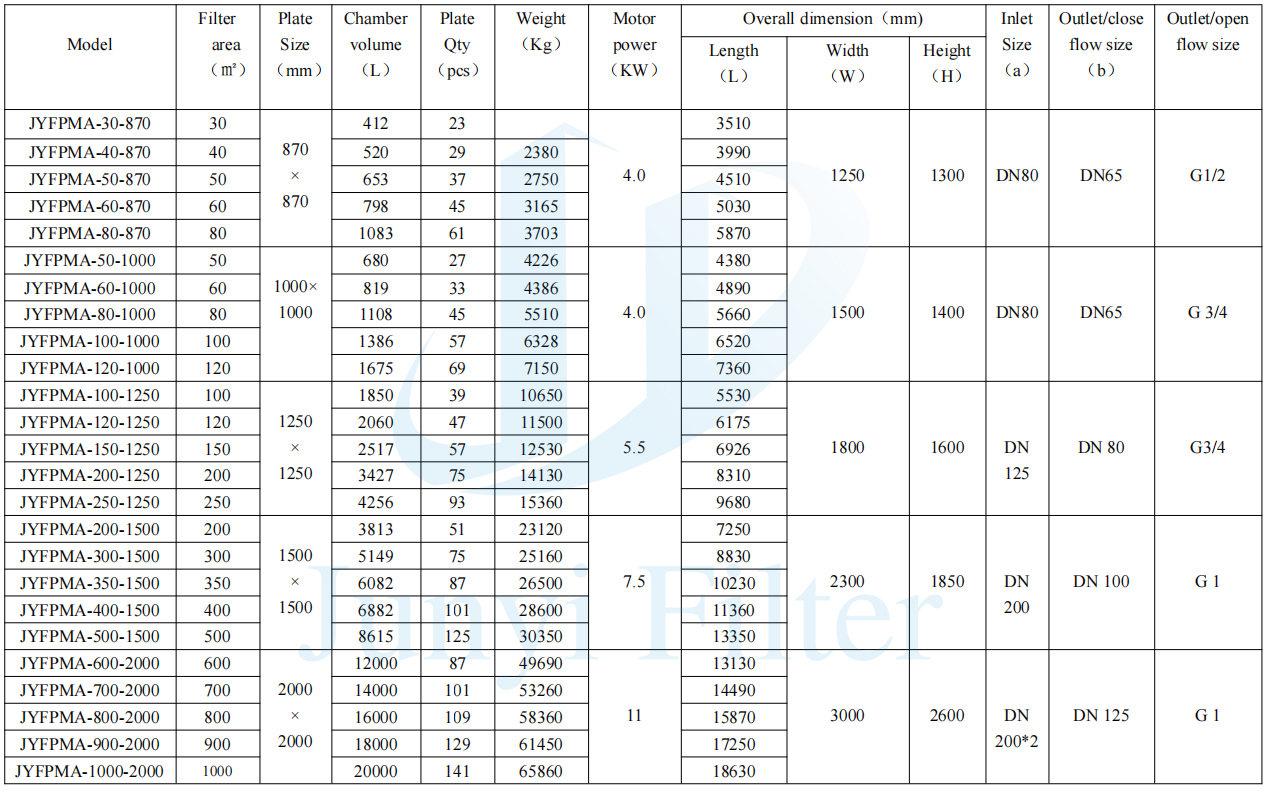

| IsiKhokelo seModeli yesihluzi | |||||

| Igama lolwelo | Umlinganiselo oqinileyo-omanzi(%) | Umxhuzulane othe ngqo weizinto eziqinileyo | Ubume bezinto eziphathekayo | PH ixabiso | Ubungakanani besuntswana eliqinileyo(umnatha) |

| Ubushushu (℃) | Ukubuyiselwa kweulwelo/eziqinileyo | Umxholo wamanzi weikeyiki yokucoca | Ukusebenzaiiyure/usuku | Umthamo/usuku | Nokuba ulweloingumphunga okanye hayi |

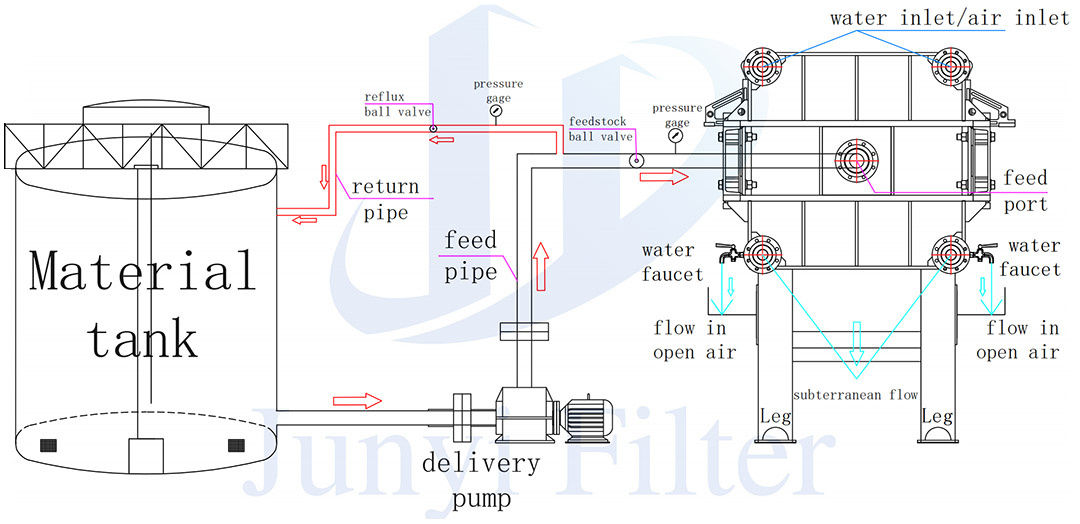

✧ Inkqubo yokutya

✧ Amashishini ezicelo

Isetyenziswa ngokubanzi kwinkqubo yokwahlula okuqinileyo-ulwelo kwi-petroleum, imichiza, idayi, isinyithi, ikhemesti, ukutya, ukuhlamba amalahle, ityuwa ye-inorganic, utywala, imichiza, isinyithi, ikhemesti, ishishini lokukhanya, amalahle, ukutya, impahla, ukukhuselwa kokusingqongileyo, amandla kunye namanye amashishini.

✧ Isihluzi seMiyalelo yoku-odola

1. Jonga kwisikhokelo sokukhetha ucofa lokucoca, isishwankathelo socofa lokucoca, iinkcukacha kunye neemodeli, khethaimodeli kunye nezixhobo ezixhasayo ngokweemfuno.

Umzekelo: Nokuba ikeyiki yokucoca ihlanjiwe okanye hayi, nokuba amanzi amdaka avuliwe okanye avaliwe,nokuba i-rack iyanyanyeka kwi-corrosion okanye hayi, indlela yokusebenza, njl., kufuneka icaciswe kwiisivumelwano.

2. Ngokweemfuno ezikhethekileyo zabathengi, inkampani yethu inokuyila kwaye iveliseiimodeli ezingezizo ezisemgangathweni okanye iimveliso ezenziwe ngokwezifiso.

3. Imifanekiso yemveliso enikwe kolu xwebhu yeyokureferensiswa kuphela. Kwimeko yotshintsho, thinaayisayi kunika isaziso kwaye owona myalelo uya kuphumelela.

✧ Umzobo we-Automatic Filter Cofa ngeNkqubo yokuGuqa ngamanzi ilaphu

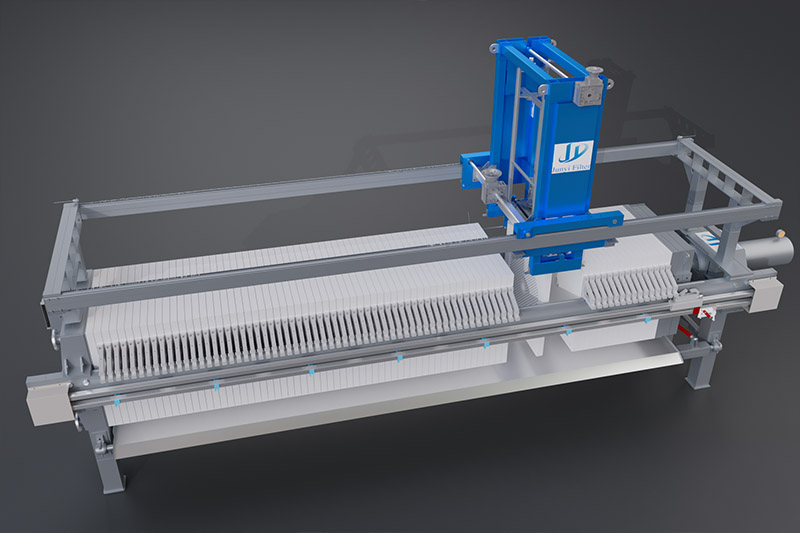

✧ I-Automatic Diaphragm Filter Cofa

✧ Ividiyo