Isihluzo esiNcinci seHydraulic 450 630 sokuHlufa kweAyini kunye nokwenza isinyithi ukucocwa kwamanzi amdaka.

✧ Iimpawu zeMveliso

A, Uxinzelelo lokuhluza≤0.6Mpa

B, Ubushushu bokucoca: 45 ℃ / ubushushu begumbi; 65℃-100/ ubushushu obuphezulu; Umlinganiselo wempahla ekrwada yeepleyiti zokucoca ubushushu ezahlukeneyo azifani.

C-1, Indlela yokukhupha i-Filtrate - ukuhamba okuvulekileyo (ukuhamba okuboniweyo): Izivalo zokucoca (iimpompo zamanzi) kufuneka zifakwe zidle amacala asekhohlo nasekunene kwipleyiti yokucoca nganye, kunye nesinki ehambelanayo. Jonga ukuhluza ngokubonakalayo kwaye ngokubanzi isetyenziselwa ulwelo olungafumanekiyo.

C-2, Indlela yokukhupha i-Filtrate - ukuhamba ngokusondeleyo (ukuhamba okungabonakaliyo):Phantsi kwesiphelo somxhesho wesihluzi sokucoca, kukho imibhobho emibini ephumayo yokuphuma, edityaniswe netanki yokuhluza. Ukuba ulwelo lufuna ukufunyanwa kwakhona, okanye ukuba ulwelo luyaguquguquka, luyanuka, lunokutsha kwaye luyaqhuma, ukuqukuqela okungabonwayo kungcono.

D-1, Ukukhethwa kwelaphu lokucoca: I-pH yolwelo imisela imathiriyeli yelaphu lokucoca. I-PH1-5 lilaphu lokucoca i-polyester eneasidi, i-PH8-14 lilaphu lokucoca i-alkaline polypropylene. Ulwelo lwe-viscous okanye okuqinileyo kuyakhethwa ukuba ukhethe ilaphu lokucoca i-twill, kunye nolwelo olungenayo i-viscous okanye oluqinileyo lukhethwa ilaphu lokucoca elicacileyo.

D-2, Ukukhetha umnatha welaphu lokucoca: Ulwelo lwahlulwe, kwaye inombolo yemesh ehambelanayo ikhethelwe ubungakanani bamasuntswana aqinileyo. Umnatha welaphu lokuhluza uluhlu lwe-100-1000 ye-mesh. Ukuguqulwa kweMicron kwimesh (1UM = 15,000 mesh---kwithiyori).

E, Unyango lomphezulu weRack: ixabiso le-PH elingathathi hlangothi okanye isiseko seasidi esibuthathaka; Umphezulu wesakhelo sokucinezela isihluzi siqhunyiswa yisanti kuqala, kwaye emva koko sitshizwe nge-primer kunye nepeyinti echasayo. Ixabiso le-PH yi-asidi eyomeleleyo okanye i-alkaline eyomeleleyo, umphezulu wesakhelo sokucofa isihluzi sigalelwe isanti, sitshizwe ngeprimer, kwaye umphezulu usongelwe ngentsimbi engatyiwayo okanye ipleyiti yePP.

F, Ukuhlamba ikeyiki yokuhluza: Xa izinto eziqinileyo kufuneka zibuyiselwe, kodwa ikeyiki yokucoca i-acidic kakhulu okanye ialkaline, sinokukhetha ukuhlamba ikeyiki ngamanzi acocekileyo phambi kokukhupha ikeyiki. Ukuba ufuna le ndlela, nceda usixelele xa ubuza.

G, Ukukhetha impompo yokondla isihluzi: Umlinganiselo oqinileyo wolwelo, ubumuncu, ubushushu kunye neempawu zolwelo zahlukile, ngoko ke kufuneka iimpompo zesondlo ezahlukeneyo. Nceda uthumele i-imeyile ukuze ubuze.

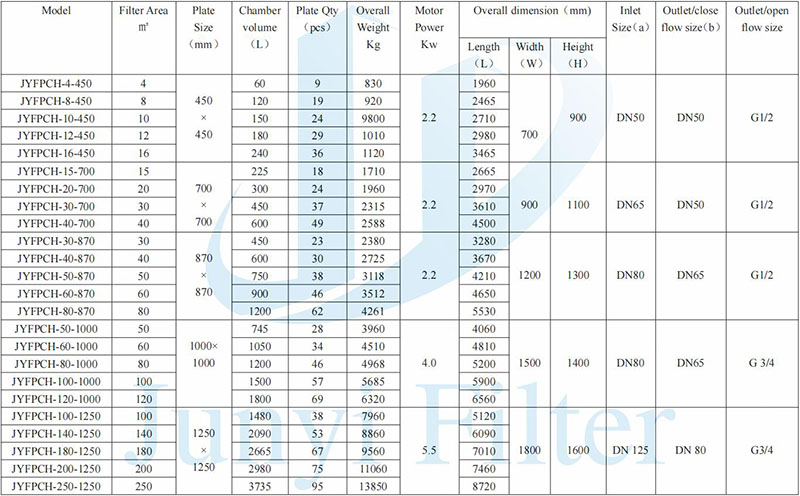

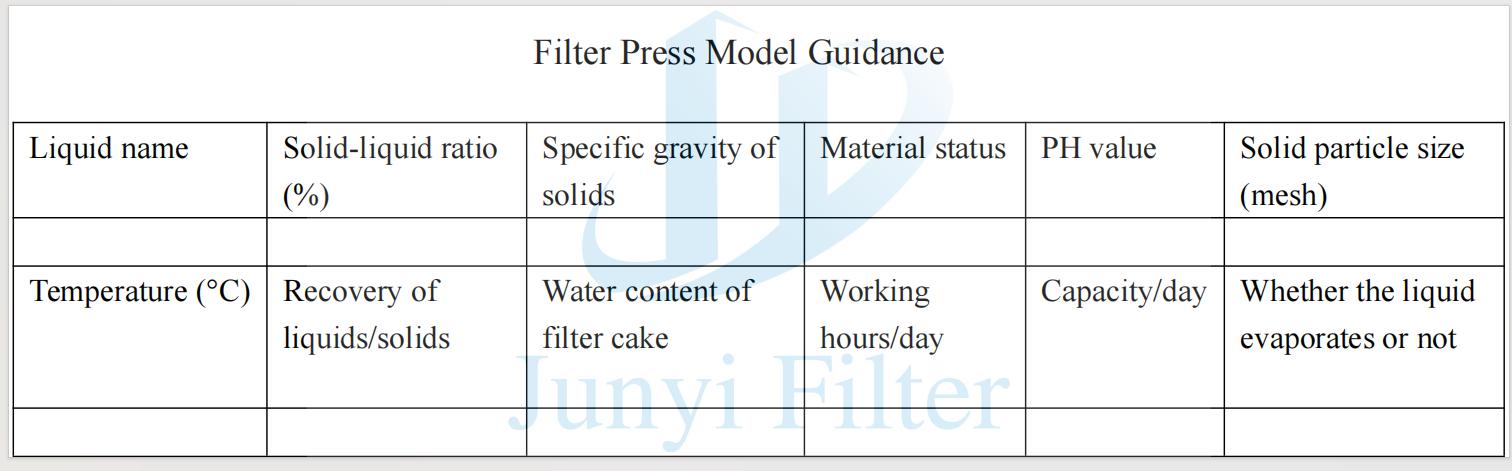

✧ IsiKhokelo seModeli yokucoca isihluzi

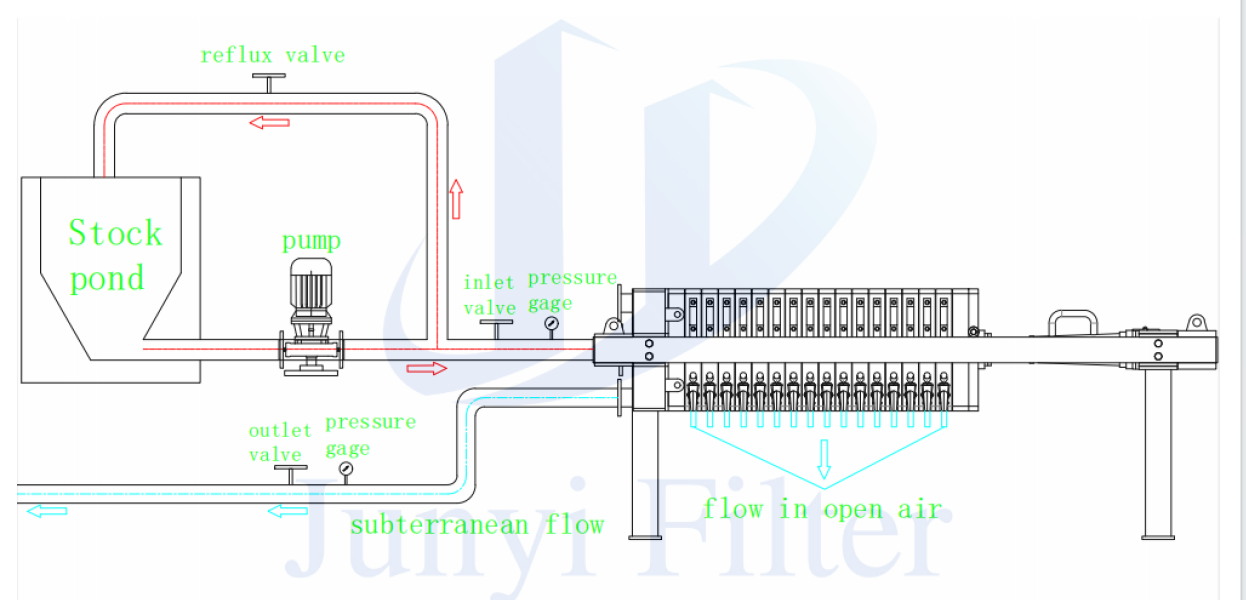

✧ Inkqubo yokutya

✧ Amashishini ezicelo

Isetyenziswa ngokubanzi kwinkqubo yokwahlula okuqinileyo-ulwelo kwi-petroleum, imichiza, idayi, isinyithi, ikhemesti, ukutya, ukuhlamba amalahle, ityuwa ye-inorganic, utywala, imichiza, isinyithi, ikhemesti, ishishini lokukhanya, amalahle, ukutya, impahla, ukukhuselwa kokusingqongileyo, amandla kunye namanye amashishini.

✧ Isihluzi seMiyalelo yoku-odola

1. Jonga kwisikhokelo sokhetho lokucoca isihluzi, ujongo lokucoca ukucoca, iinkcukacha kunye neemodeli, khetha imodeli kunye nezixhobo ezixhasayo ngokweemfuno. Sineqela lobuchwephesha lobuchwephesha ekuncedeni ukhethe imodeli efanelekileyo, wamkelekile ukuba ushiye iinkcukacha zakho zoqhagamshelwano ukuze ubuze.

2. Ngokweemfuno ezikhethekileyo zabathengi, inkampani yethu inokuyila kwaye ivelise iimodeli ezingekho kumgangatho okanye iimveliso ezenziwe ngokwezifiso. Umzekelo: Ingaba ikhekhe lokucoca lihlanjwe okanye cha, nokuba i-filtrate ivuliwe okanye ivaliwe, nokuba i-rack ayinqande ukubola okanye ayikho, indlela yokusebenza, njl.

3. Imifanekiso yemveliso enikwe kolu xwebhu yeyokureferensiswa kuphela. Kwimeko yotshintsho, asiyi kunika isaziso kwaye owona myalelo uya kuphumelela.

Iimfuno zokusebenzisa izihluzi zokucoca

1. Ngokweemfuno zenkqubo yokwenza uqhagamshelo lombhobho, kwaye wenze uvavanyo lokungena kwamanzi, ukubona ukuxinana komoya wombhobho;

2. Ukudibanisa igalelo lombane (isigaba se-3 + singathathi hlangothi), kungcono ukusebenzisa ucingo lomhlaba kwikhabhinethi yokulawula umbane;

3. Uqhagamshelwano phakathi kwekhabhinethi yolawulo kunye nezixhobo ezijikelezayo. Ezinye iingcingo ziqhagamshelwe. Iitheminali zomgca wokuphuma kwikhabhinethi yolawulo zibhaliwe. Jonga kumzobo wesiphaluka ukujonga i-wiring kwaye uyidibanise. Ukuba kukho ukukhululeka kwi-terminal emiselweyo, cinezela kwakhona;

4. Gcwalisa isikhululo se-hydraulic nge-46 # i-oyile ye-hydraulic, i-oyile ye-hydraulic kufuneka ibonakale kwi-tank observation window. Ukuba isihluzo sokucoca sisebenza ngokuqhubekayo kwiiyure ezingama-240, buyisela okanye ucofe ioyile yehydraulic;

5. Ukufakwa kwe-cylinder pressure gauge. Sebenzisa i-wrench ukuphepha ukujikeleza ngesandla ngexesha lofakelo. Sebenzisa i-O-ring ekudibaniseni phakathi kwe-gauge yoxinzelelo kunye ne-cylinder yeoli;

6. Ngexesha lokuqala i-cylinder yeoli ibaleka, i-motor ye-hydraulic station kufuneka ijikelezwe ngasekunene (iboniswe kwi-motor). Xa i-cylinder yeoli iqhutywe phambili, isiseko sokulinganisa uxinzelelo kufuneka sikhuphe umoya, kwaye i-cylinder yeoli kufuneka iqhutywe ngokuphindaphindiweyo ngaphambili nangasemva (uxinzelelo lomda ophezulu we-gauge ye-pressure gauge yi-10Mpa) kwaye umoya kufuneka ukhutshwe kanyekanye;

7. Umshicileli wokucoca uqhuba okokuqala, khetha imo yezandla yekhabhinethi yokulawula ukuqhuba imisebenzi eyahlukeneyo ngokulandelelana; Emva kokuba imisebenzi iqhelekile, ungakhetha imo ezenzekelayo;

8. Ukufakwa kwelaphu lokucoca. Ngexesha lokusebenza kwesilingo sokucoca, ipleyiti yokucoca kufuneka ixhotyiswe ngelaphu lokucoca kwangaphambili. Faka ilaphu lokucoca kwipleyiti yokucoca ukuze uqinisekise ukuba ilaphu lokucoca lisicaba kwaye akukho zikreke okanye ukugqithelana. Tyhila ngesandla ipleyiti yokucoca ukuqinisekisa ukuba ilaphu lokucoca limcaba.

9. Ngethuba lokusebenza kokucoca ukucoca, ukuba kwenzeka ingozi, umqhubi ucofa iqhosha lokumisa likaxakeka okanye utsale intambo yongxamiseko;

Iimpazamo eziphambili kunye neendlela zokusombulula ingxaki

| Impazamo eyenzekayo | Impazamo yoMgaqo | Ukulungisa ingxaki |

| Ingxolo enkulu okanye uxinzelelo olungazinzanga kwi-hydraulic system | 1, Impompo yeoli ayinanto okanye umbhobho wokufunxa ioyile uvaliwe. | I-oyile ye-refueling, ukusombulula ukuvuza kombhobho wokufunxa |

| 2, Umphezulu wokutywina wepleyiti yokucoca ubanjwe nge-misc. | Coca iindawo zokutywina | |

| 3, Umoya kwisekethe yeoli | Ukukhupha umoya | |

| 4, Impompo yeoli yonakele okanye igugile | Ukubuyisela okanye ukulungisa | |

| 5, Ivalve yoncedo ayizinzanga | Ukubuyisela okanye ukulungisa | |

| 6, Ukungcangcazela kombhobho | Ukuqinisa okanye ukuqinisa | |

| Ukungonelanga okanye akukho xinzelelo kwi-hydraulic system | 1, Umonakalo wempompo yeoli | Ukubuyisela okanye ukulungisa |

| uhlengahlengiso | |

| 3, i-oyile viscosity iphantsi kakhulu | Ukutshintshwa kweoli | |

| 4, Kukho ukuvuza kwinkqubo yempompo yeoli | Ukulungisa emva koviwo | |

| Uxinzelelo lwe-cylinder olunganeleyo ngexesha loxinzelelo | I-1, eyonakeleyo okanye ibambe ivalve yoxinzelelo oluphezulu | Ukubuyisela okanye ukulungisa |

| 2, Ivalve yokubuyisela umva eyonakeleyo | Ukubuyisela okanye ukulungisa | |

| 3. Itywina elikhulu elonakeleyo lepiston | ukutshintshwa | |

| 4, Ipiston encinci eyonakeleyo "0" itywina | ukutshintshwa | |

| 5, impompo yeoli eyonakeleyo | Ukubuyisela okanye ukulungisa | |

| 6, Uxinzelelo alulungiswanga kakuhle | lungisa kwakhona | |

| Uxinzelelo lwesilinda olunganelanga xa ubuya | I-1, Ivalve yokunciphisa uxinzelelo oluphantsi okanye yonakele | Ukubuyisela okanye ukulungisa |

| 2, Itywina elincinci lepiston elonakeleyo | ukutshintshwa | |

| 3, ipiston encinci eyonakeleyo "0" itywina | ukutshintshwa | |

| Ipiston ekhasayo | Umoya kwisekethe yeoli | Ukubuyisela okanye ukulungisa |

| Ingxolo enkulu yothumelo | 1, Ukuthwala umonakalo | ukutshintshwa |

| 2. Ukubetha okanye ukunxiba | Ukubuyisela okanye ukulungisa | |

| Ukuvuza okunzulu phakathi kweepleyiti kunye nezakhelo |

| ukutshintshwa |

| 2, Inkunkuma kumphezulu wokutywina | Coca | |

| 3. Ilaphu lokuhluza elinemisongo, ukuwela, njl. | Ufanelekile ukugqiba okanye ukutshintshwa | |

| 4. Amandla oxinzelelo angonelanga | Ukunyuka okufanelekileyo kwamandla oxinzelelo | |

| Ipleyiti kunye nesakhelo zophukile okanye zikhubazekile | 1, Uxinzelelo lwesihluzi luphezulu kakhulu | yehlisa uxinzelelo |

| 2, ubushushu bezinto eziphezulu | Amaqondo obushushu athotywe ngokufanelekileyo | |

| 3, Amandla oxinzelelo aphezulu kakhulu | Lungisa amandla oxinzelelo ngokufanelekileyo | |

| 4.Ukuhluza ngokukhawuleza okukhulu | Ukunciphisa izinga lokuhluza | |

| 5. Umngxuma wokutyisa ovaliweyo | Ukucoca umngxuma wesondlo | |

| 6, Ukumisa embindini wokuhluza | Musa ukuyeka embindini wokuhluza | |

| Inkqubo yokugcwalisa isebenza rhoqo | I-1, Ivalve yokuhlola i-hydraulic ayivalwanga ngokuqinileyo | ukutshintshwa |

| 2, Ukuvuza kwi-cylinder | Ukutshintshwa kweesilinda ze-cylinder | |

| Ukusilela kwevalvu yokubuyisela umva kweHydraulic | I-Spool ibambekile okanye yonakele | Hlukanisa kwaye ucoce okanye ubuyisele ivalve yendlela |

| Itroli ayinakutsalwa ngasemva ngenxa yempembelelo yangasemva naphambili. | 1, Uxinzelelo lwesekethe yeoli yeoyile ephantsi | lungisa |

| 2, Uxinzelelo lwe-relay yoxinzelelo luphantsi | lungisa | |

| Ukungaphumeleli ukulandela iinkqubo | Ukungaphumeleli kwecandelo le-hydraulic system, inkqubo yombane | Lungisa okanye utshintshe ngokubonakalayo emva kokuhlolwa |

| Umonakalo we-diaphragm | 1, uxinzelelo lomoya olungonelanga | Ukuncitshiswa koxinzelelo lweendaba |

| 2、Ukutya okungonelanga | Ukucinezela emva kokuzalisa igumbi ngezinto eziphathekayo | |

| 3, Into yasemzini igqobhoze idiaphragm. | ukususwa kwezinto zangaphandle | |

| Ukugoba umonakalo kumqadi ophambili | 1. Iziseko eziphantsi okanye ezingalinganiyo | Hlaziya okanye wenze kwakhona |