I-High-Pressure Diaphragm Filter Press-Ikeyiki yokufuma okuPhantsi, i-Automated Sludge Dewatering

Intshayelelo yeMveliso

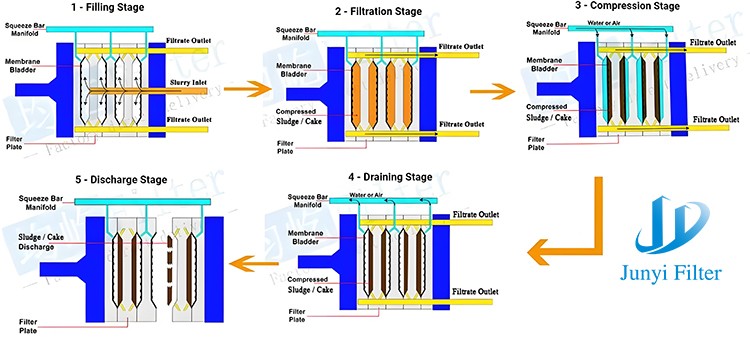

Ii-membrane filter cofasisixhobo sokwahlula esiqinileyo esilulwelo.

1.Ishishini lokukhuselwa kokusingqongileyo (ukucocwa kwamanzi amdaka kunye nokucocwa kodaka)

Iziko likamasipala lokucocwa kwamanzi amdaka:

Isetyenziselwa ukugxininiswa kunye nokukhupha amanzi (okufana nodaka olusebenzayo, udaka olugayiweyo), lunokunciphisa umthamo wokufuma ukusuka kwi-98% ukuya ngaphantsi kwe-60%, yenze kube lula ukutshiswa okulandelayo okanye ukulahla inkunkuma.

Ukucocwa kwamanzi amdaka kwimizi-mveliso:

Ukunyangwa kwamanzi okumanzi aphezulu kunye nokungcola okuphezulu kwe-sludge efana ne-electroplating sludge, ukudaya i-sludge, kunye ne-papermaking sludge.

Ukwahlulwa kwesinyithi esinzima esisuka kumanzi amdaka kwipaki yoshishino lweekhemikhali.

Ukuchithwa komlambo/ichibi: Intlenga iphelelwa ngamanzi emzimbeni ngokukhawuleza, inciphisa iindleko zokuhamba kunye nokulahla.

Izinto eziluncedo:

✔ Isiqulatho sokufuma esisezantsi (ukuya kuthi ga kwi-50% -60%) sicutha iindleko zokulahla

✔ uyilo olungagungqiyo kukonakala lunokuphatha udaka oluneasidi kunye nealkaline

2. Ishishini leMigodi kunye neMetallurgy

Unyango lwemisila:

Ukunkcenkceshelwa kodaka oluludaka olusuka kwintsimbi ekrwada, intsimbi ekrwada yobhedu, intsimbi ekrwada yegolide kunye nezinye izimbiwa, ukubuyisela ubutyebi bamanzi kunye nokunciphisa ukuhlala komhlaba kumachibi eentsalela zezimbiwa.

Ukuncitshiswa koxinaniso:

Ukuphucula ibakala lokugxila (njenge-lead-zinc ore, i-bauxite) yenza kube lula ukuthutha kunye ne-smelt.

Unyango lwe-Metallological slag:

Ukwahlula okuqinileyo kolwelo lwenkunkuma njenge-slag yentsimbi kunye nodaka olubomvu, kunye nokubuyiswa kweentsimbi eziluncedo.

Izinto eziluncedo:

✔ Uxinzelelo oluphezulu luphumela kwikeyiki yesihluzi esinobumanzi obusezantsi njenge-15% -25%

✔ Iipleyiti zokucoca ezikwaziyo ukunxiba zifanelekile kwiiminerali ezinobunzima obuphezulu

3. Ishishini leMichiza

Imichiza emihle:

Ukuhlamba kunye nokuphelelwa ngamanzi emzimbeni kwiipowders ezifana ne-pigments (Titanium Dioxide, i-Iron oxide), idayi, i-calcium carbonate, i-kaolin, njl.

Izichumisi kunye nezitshabalalisi:

Ukwahlula kunye nokumisa iimveliso ze-crystalline (ezifana ne-ammonium sulfate, urea).

Ishishini lePetrochemical:

I-Catalyst recovery, unyango lwe-oyile ye-sludge (njenge-oyile ye-oyile evela kwiindawo zokucocwa kweoli).

Izinto eziluncedo:

✔ I-Acid kunye ne-alkali enganyangekiyo (i-PP, i-rubber lined steel) ifanelekile kwimidiya ephazamisayo

✔ Ukusebenza okuvaliweyo kunciphisa ukukhutshwa kwegesi eyityhefu

4. Ubunjineli bokutya kunye neBiyotechnology

Ukwenziwa Kwesitatshi:

Ukomisa kunye nokuhlamba umbona kunye nesitashi setapile, usebenzisa ezinye ii-centrifuges ukunciphisa ukusetyenziswa kwamandla.

Umzi mveliso wotywala:

Ukwahlula igwele, i-amino acids, kunye ne-antibiotiki mycelium.

Imveliso yesiselo:

Ukucofa kunye nokuphelelwa ngamanzi emzimbeni kwimash yebhiya kunye neentsalela zeziqhamo.

Izinto eziluncedo:

✔ Yenziwe ngentsimbi yokutya-ibakala lokutya okanye izinto zePP, ukuhlangabezana nemigangatho yococeko

✔ Ukuphelelwa ngubushushu obuphantsi bugcina izithako ezisebenzayo